About FactoryLogix MES

FactoryLogix MES pricing

FactoryLogix MES does not have a free version. FactoryLogix MES paid version starts at USD 40,000.00/one-time.

Alternatives to FactoryLogix MES

FactoryLogix MES Reviews

Feature rating

- Industry: Electrical/Electronic Manufacturing

- Company size: 501–1,000 Employees

- Used Daily for 2+ years

-

Review Source

Factory Logix saves us money and time

Any time we have had issues with the system, we needed to understand how something could be done in the system, or just general questions, the Aegis Support Team have never failed to be there for us. They are a World-Class group and always go above and beyond to help us out. With the features that Aegis' FactoryLogix offers, it has helped us get new customers as customers are asking for more and more things. We view FactoryLogix as both a manufacturing execution system and a sales tool! Aegis gives us a competitive advantage, enabling us to meet our customers' changing requirements, ultimately helping us to capture more business and consistently deliver exceptional products and customer service.

Pros

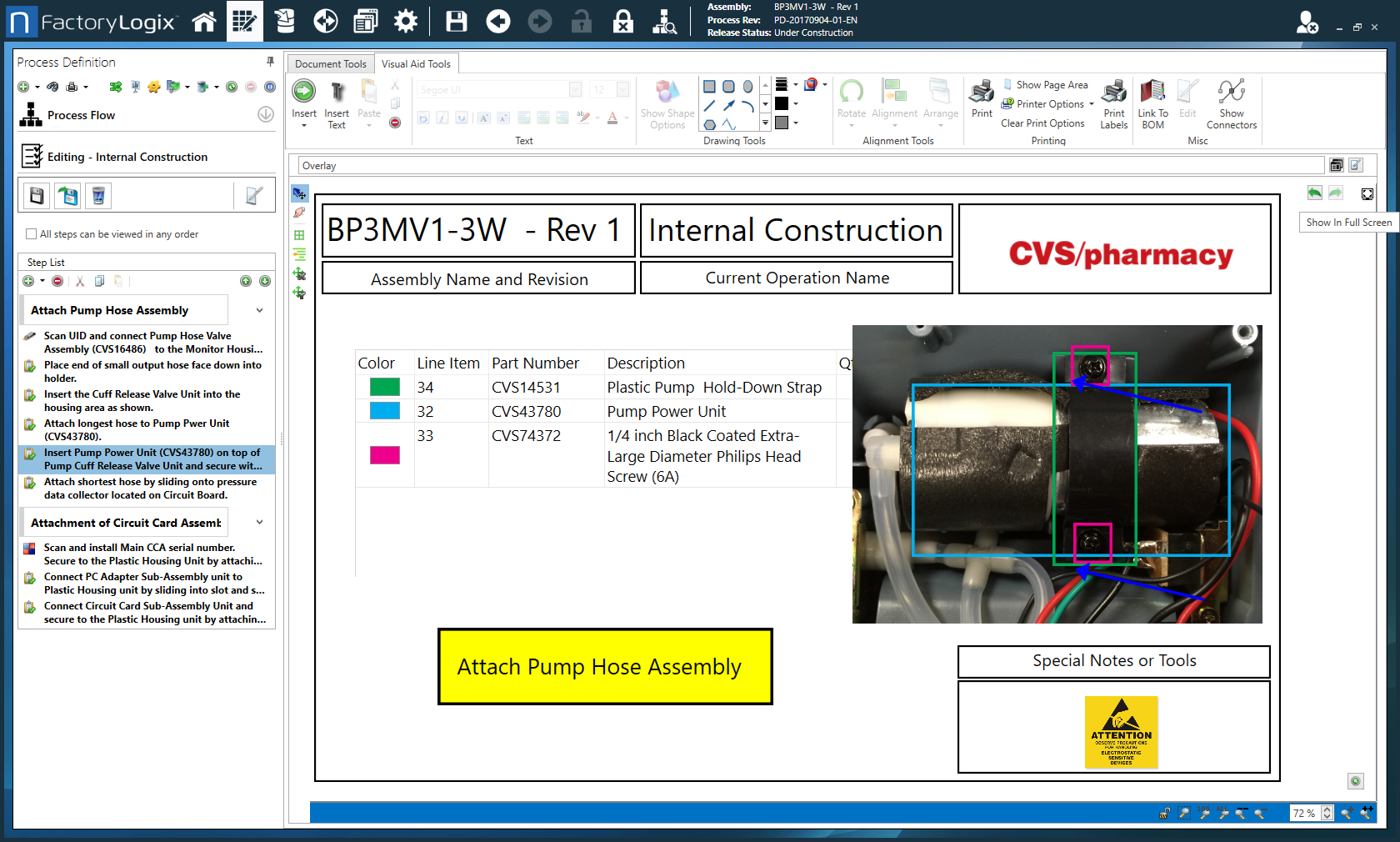

One of the major issues we had was paperwork on our production floor. The creation, distribution, and updating of paper documents on our production floor creates an extensive amount of work for our staff. With FactoryLogix we have gotten rid of all the paperwork we were creating. We went from having many cabinets full of paper documentation to all of our documentation now electronic. No longer do we have pages and pages for each work order. With FactoryLogix, if anything changes, we go into the system and immediately make any changes required, and the production floor gets those changes instantly. The entire documentation process is real-time and much easier. We can also now track the product from the cradle to the grave.

Additionally, we can let our customers know if items inside any of the units have been replaced due to using Sub-Assembly collection capabilities. FactoryLogix has saved us much in the way of dollars and time of creating production orders. When it comes to reporting, while this is an area of the solution that we do not use as much, anytime we need something, a pre-existing report can be leveraged, or a new report can be created. The depth of information captured in the system provides us a rich data repository that can support any level of data investigation or reporting that we need.

Cons

We do not have any negatives to report about FactoryLogix. Whenever we were not sure how to use the solution to meet our needs, the Aegis team was always there to support us and help us with any challenge we encountered.

- Industry: Electrical/Electronic Manufacturing

- Company size: 201–500 Employees

- Used Daily for 2+ years

-

Review Source

Simply put, nothing but positive experiences.

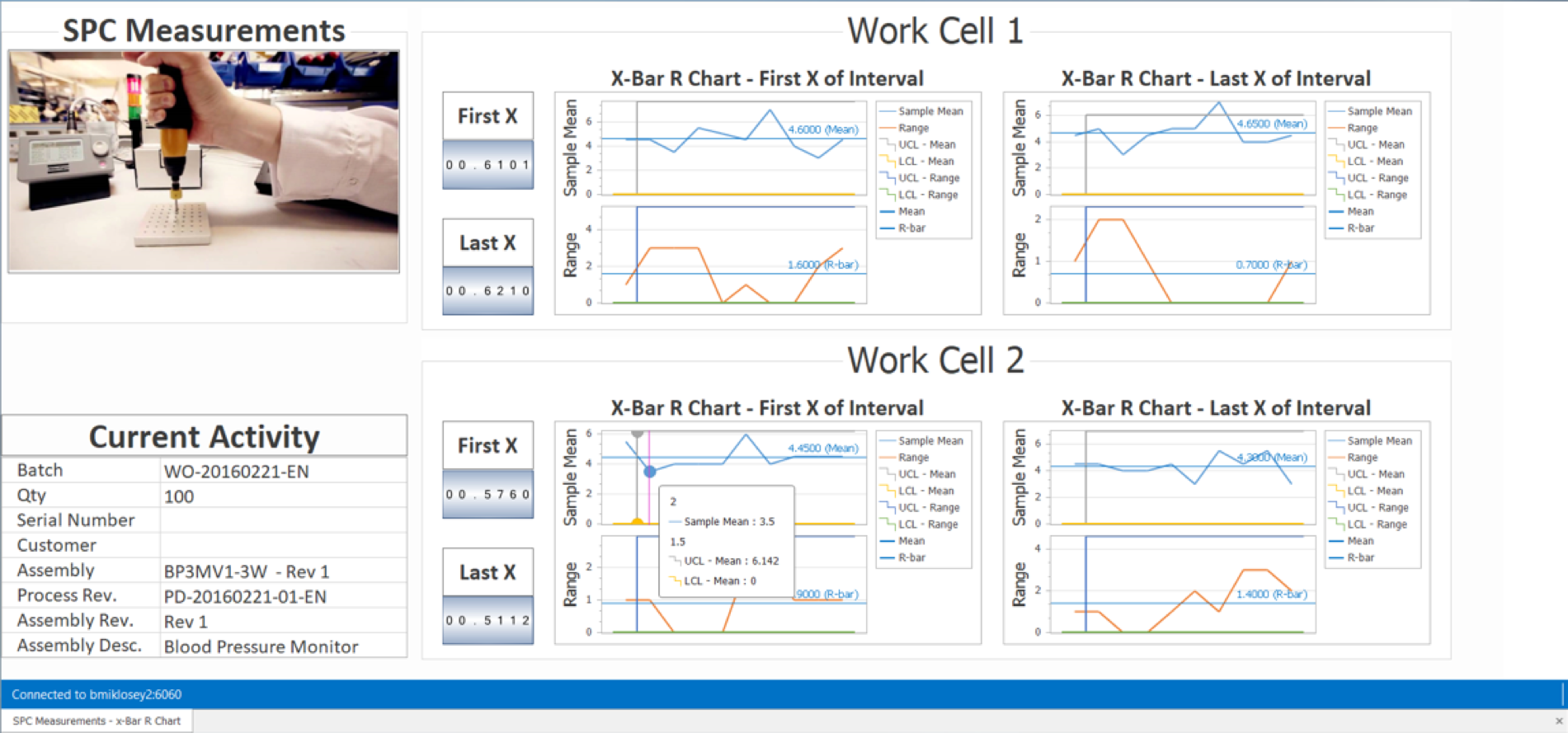

On the back end, the amount of data collected is almost limitless. FactoryLogix has full defect history (who, when, where, what, how) that can be exported into Excel or automatically presented into charts, graphs, reports, and live dashboards. This data can also drive automatic email alerts based on almost any criteria you can think of (DPMO, yield, machine status). On the pricing side, you pay for what you need. It is module and license-driven and can easily expand as you expand your requirements. The Aegis team is proactive in offering new ways that we can leverage the solution to drive additional improvements. We are pleased to be part of the Aegis customer community and look forward to a continued relationship with them.

Pros

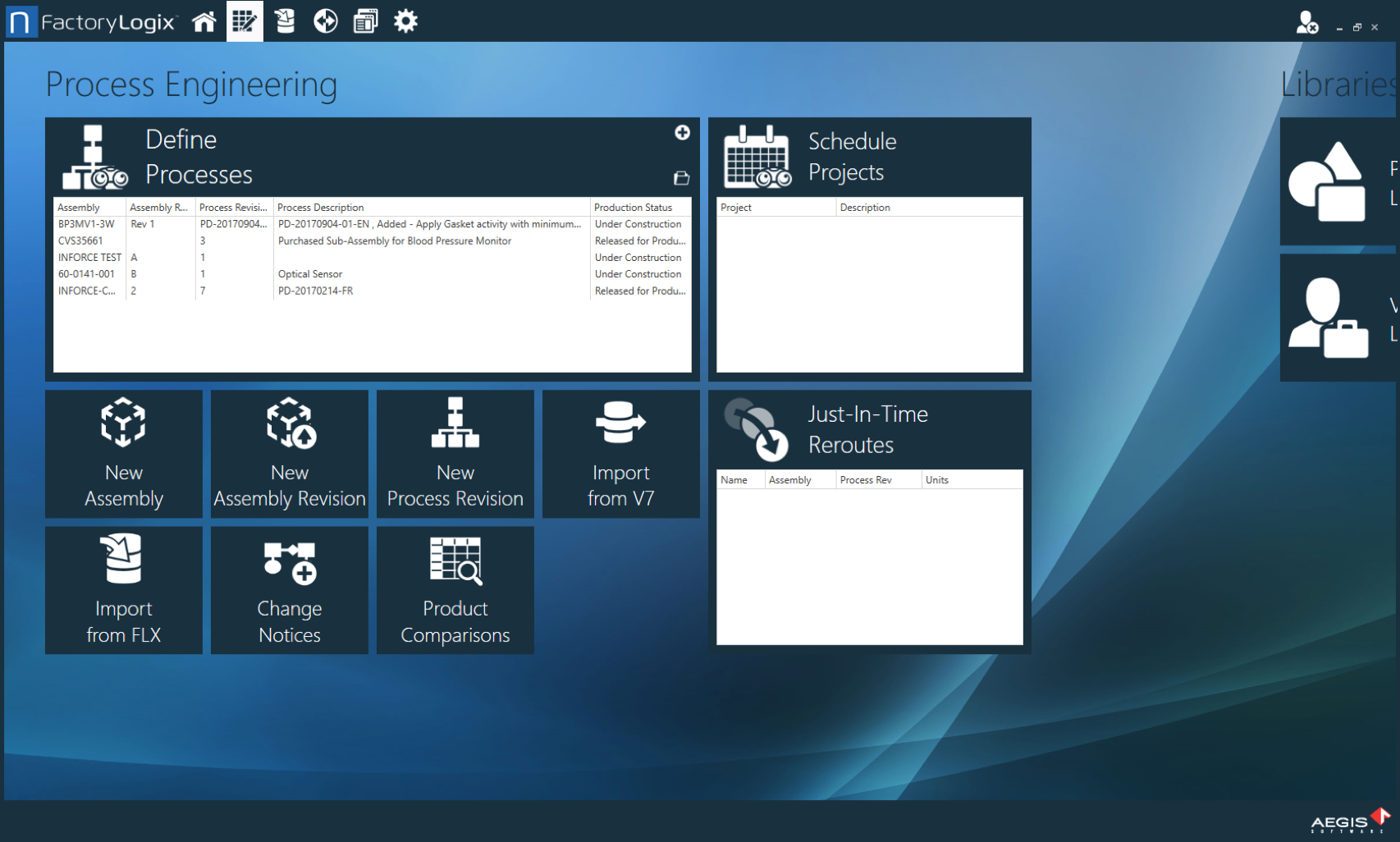

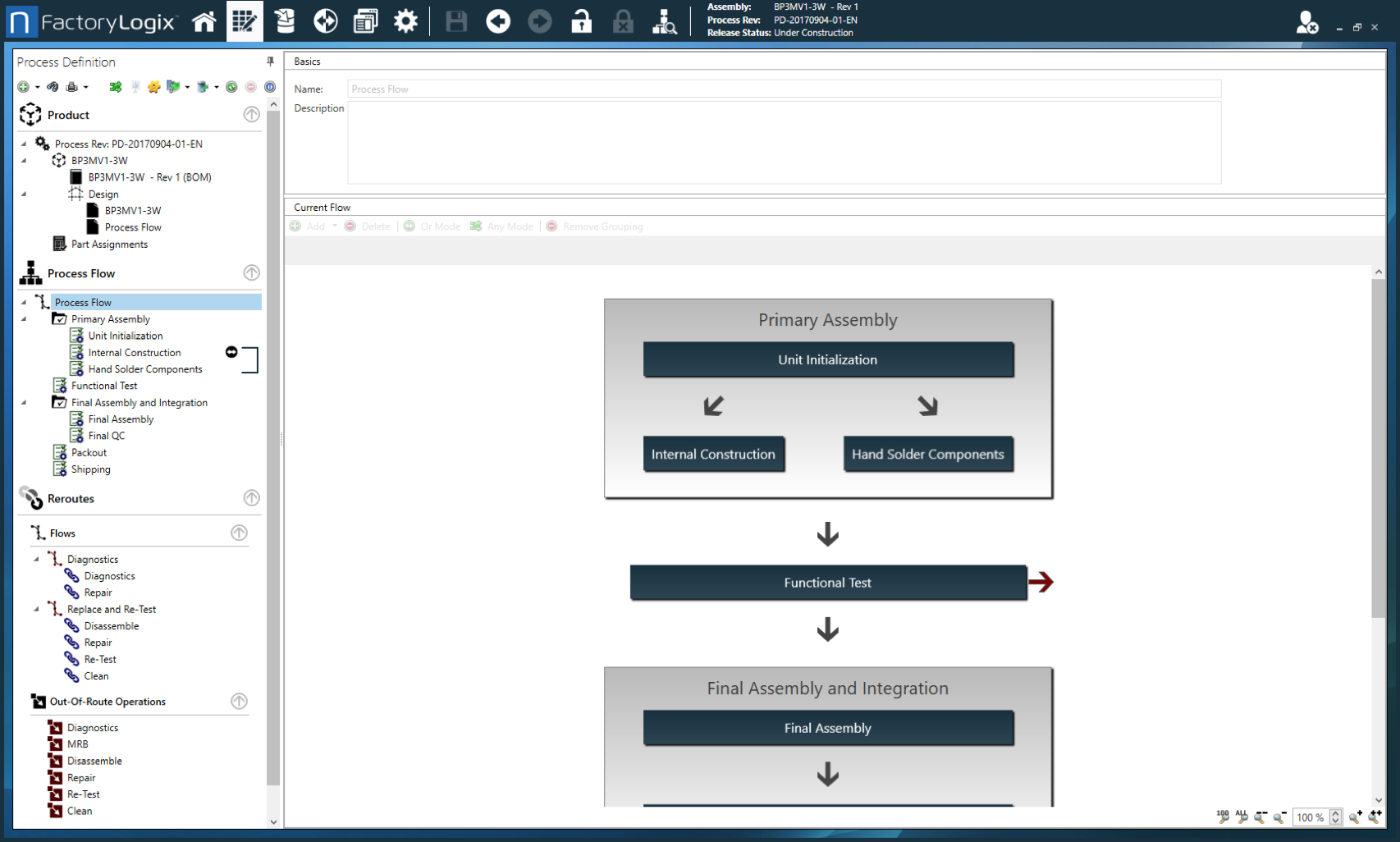

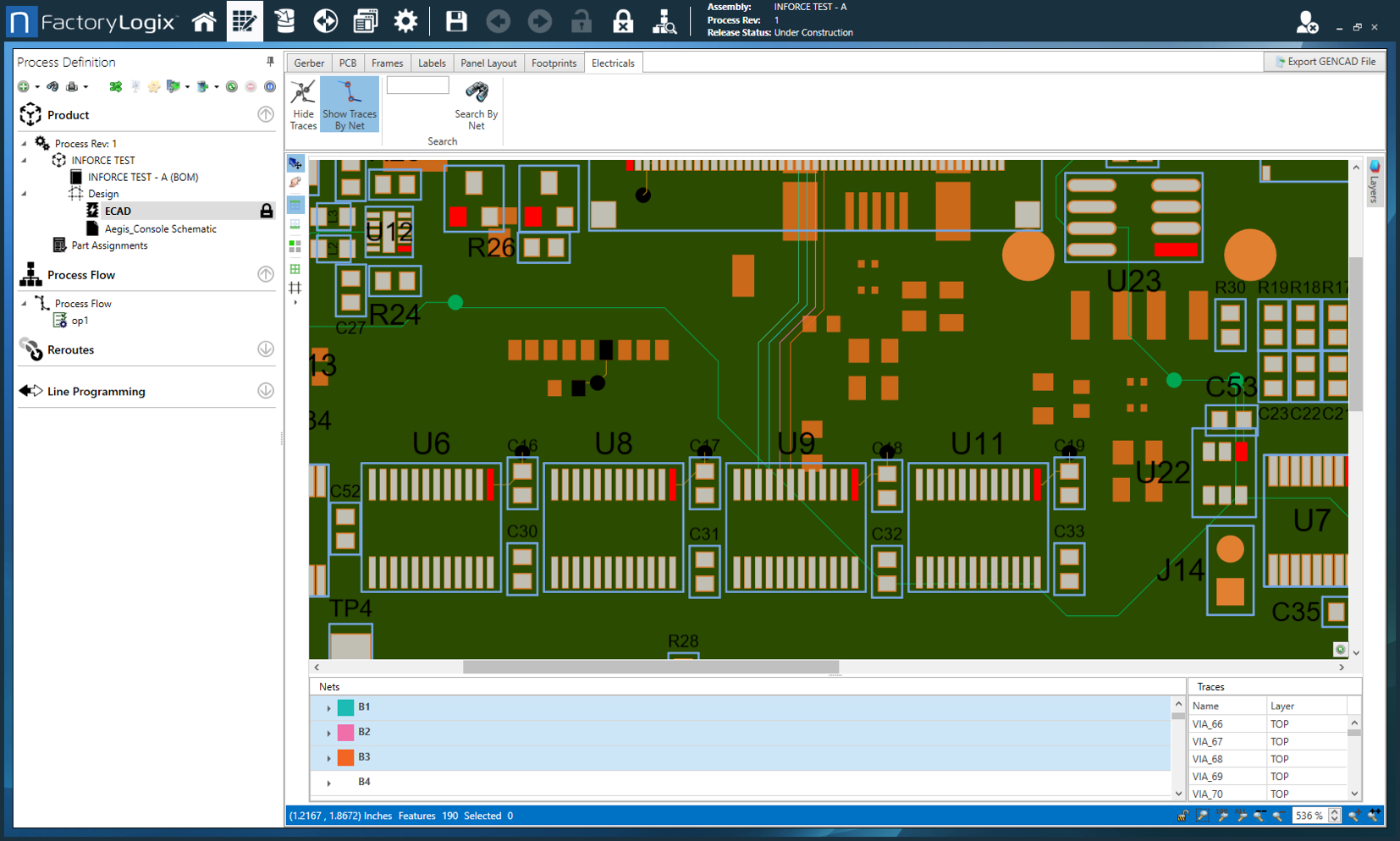

As a company specializing in the development of advanced strategic, operational, and tactical communication solutions, we use FactoryLogix to create our production processes. We are currently expanding our usage of FactoryLogix to track our entire circuit board production process. FactoryLogix is very versatile with sources of CAD file data that easily imports. FactoryLogix can find all matching packages and uses your X/Y placement files to assign the references to the appropriate packages. We import all BOMs from their original Excel format. Also, you can import 3D CAD files for mechanical assemblies. Their newest release has expanded their 3D CAD capabilities and is truly amazing looking. Once you have your process set up and process detail page templates designed, you can quickly import new assembly files and generate your process details efficiently. Operators can view them digitally while scanning boards through their process, following multiple guided steps if needed while recording any assembly data (measurements taken, defect data, etc.). They can also send feedback to your manufacturing engineers. FactoryLogix can ensure that the assembly does not get started at a process if it has any open defects, has not passed the previous step successfully, or can even check to make sure enough time has elapsed since the previous step. It can also perform multiple checks when someone tries to pass it through their process. Additionally, FactoryLogix has sample inspection methods

Cons

I don’t really have any negatives to report regarding the software solution. To date, we are happy with the capabilities, and we look forward to expanding our usage of the system in the near future.

- Industry: Electrical/Electronic Manufacturing

- Company size: 1,001–5,000 Employees

- Used Daily for 2+ years

-

Review Source

Manufacturing superior quality products with FactoryLogix

Aegis’ customer support team has been very accommodating when I have needed to reach out to them. They are very knowledgeable about the product they are supporting and always eager to help. There is also a customer support portal that offers numerous training videos. The portal has been a very helpful tool when new employees need introductory training. As a power user, I often refer to these videos as a refresher or learn new functionalities.

Pros

FactoryLogix has extensive quality management capabilities throughout the entire manufacturing process. As an OEM manufacturer with large work order quantities, the in-line first article feature in FactoryLogix allows us to catch and prevent incorrect builds, which provides high dollar cost avoidance. Regarding data collection, before using FactoryLogix, defects were generally applied at the component level making it difficult to extract useful information when investigating root cause. Now with FactoryLogix, we can enforce the level at which defects are assigned, which could be at assembly, component, or even down to the pin of a circuit board. This level of granularity gives us the rich data needed for accurate and efficient root cause analysis. FactoryLogix will automatically prompt the operator to perform quality checks periodically during the production process, ensuring that critical quality parameters are being met throughout production. Having the ability to catch non-conformances, while in-process, has dramatically reduced our amount of rework and associated costs. Additionally, we have instantaneous access to all quality data collected throughout the entire process, which we did not have before using FactoryLogix. This real-time access to information enables us to instantly trigger alarms if something is not performing as intended.

Cons

The response time of the software can sometimes be painful

- Industry: Electrical/Electronic Manufacturing

- Company size: 51–200 Employees

- Used Daily for 2+ years

-

Review Source

BTW has complete control, traceability & visibility with FactoryLogix

We pride ourselves in delivering top-notch service to our customers, so we expect this from vendors. While we are pleased with the benefits that continue to derive by using FactoryLogix, the product is only a piece of what we expected when we chose Aegis. The team behind the product was crucial in the overall implementation success, but also our ongoing success. Throughout our journey with Aegis Software, service and support has been unwavering and rapid when we need it. Their knowledge, responsiveness, and support have been necessary, given the critical role that FactoryLogix plays in our overall business. They are a true partner and dedicated to helping manufacturers be best-in-class.

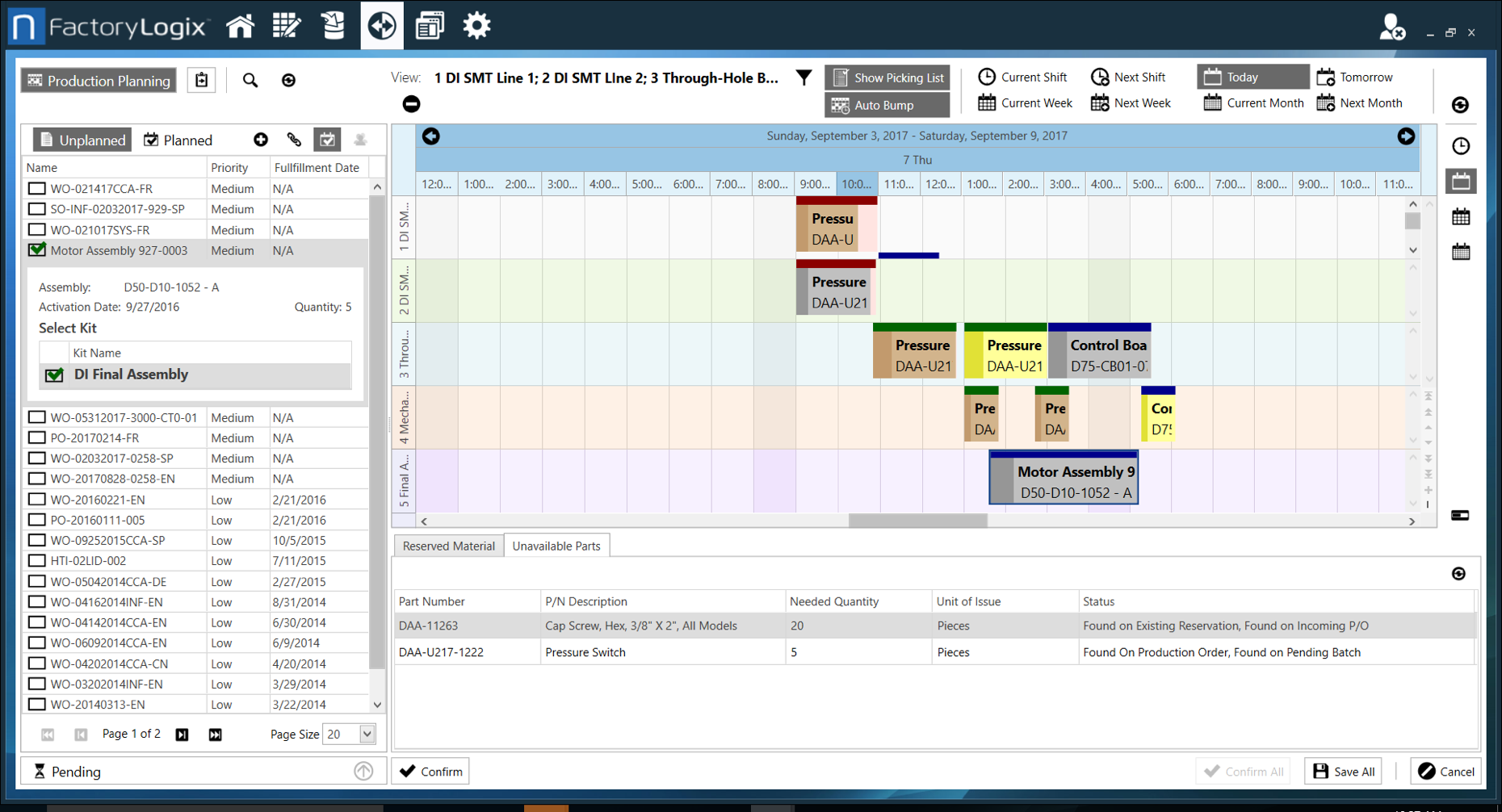

Pros

Before we implemented FactoryLogix, one of our biggest challenges was related to paper documentation and enforcing its use and revision on the production floor. Paper documents would often get lost, or an incorrect document would be used that ultimately caused quality issues and negatively impacted our production schedules. When it comes to WIP tracking, before FactoryLogix, if we wanted to know the status of WIP, account managers would have to walk around the production floor to locate where their products were in process. FactoryLogix WIP tables and dashboards make all that a thing of the past.

In our manufacturing environment, accurate and in-depth traceability is essential. With FactoryLogix, traceability is automatically inherent throughout the platform. In an instant, we can find out who did rework, when, why, and the entire history of the assembly for anyone who needs to see it. Without FactoryLogix’ rich quality data collection and reporting capabilities, our employees would still be wasting time manually entering quality data into spreadsheets to track and report on our quality metrics.

While product features are important, it is sometimes challenging to find feature-rich and flexible software that is not complex or hard to use. So, ease of use was essential to us when we initially decided to select and implement FactoryLogix. We knew that if the solution wasn’t easy to use, we would have user adoption issues and never achieve the return or benefits we

Cons

We do not have anything to report on the negative side for this software.

- Industry: Maritime

- Company size: 51–200 Employees

- Used Daily for 2+ years

-

Review Source

FactoryLogix MES is used in our Suzhou factory operations and throughout our company’s EMS...

Pros

There are several advantages we can note using Aegis:

Visibility – The most essential benefit using FactoryLogix I find as an engineering manager is the immediate information I have to our operation’s performance and the insight it offers to make improvements in both quantitative and qualitative ways.

Compliance Assurance – One key area of our operations where we rely on Aegis MES is in our packing area for finished goods. It is here where the system’s extensive validations ensure we are delivering accurate and the highest quality products to our customers

Customer support – Whenever we have needed assistance, we have direct and immediate contact to their support staff without having to deal with an automated voice menu or being put on hold. They have a sense of urgency when responding to us, listening to our needs, and delivering solutions in a timely manner.

Factory-wide coverage and configurability – FactoryLogix supports our entire factory from automated electronics assembly to manual system builds, with its MES interface for our assemblers, inspectors, and technicians, and with connections to our assembly, inspection, and test equipment. All of this is covered with standard capabilities that required little customization, and as our manufacturing environment continues to change over the eight-plus years since first using Aegis software, its extensive configurability enables us to change processes, rules, and behaviors as necessary to meet our own customers’ expec

Cons

We do not have anything to report on the negative side for this software.